We start with the best people, engineering expertise and over several decades of knowledge and know-how of material handling, process weighing and control in cement production. Our team then provides integrated products, services and solutions to help customers in the cement industry optimize their quality and productivity resulting in increased availability, better product quality and lower lifetime investment costs. Our solutions are wide ranged applicable for Mining , Raw Material handling, Raw Meal preparation, Kiln feed control, Cement Mill feeding, Silo Level monitoring, Online Check Weighers, Integrated Bag counting and Monitoring Systems for Packing House, Logistic Solutions etc. Achieving homogeneity in your kiln feed is vital. It affects everything, from the stability of your pyro process to the quality of your end product. The impact of a poorly balanced raw meal composition in kiln feed is felt on fuel efficiency, refractory life and, most evidently, your bottom line. So how do we make sure your raw feed remains consistent? Acme has the right solutions….. Dependability. Reliability. Stability, Quality…… Everything counts with high quality cement

Application

Offerings

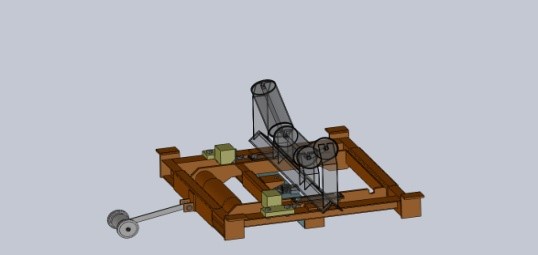

Apron Weigh Feeder

ACME reinvents Hot Sinter/DRI dosing with new generation heavy duty Apron Weigh Feeder

Belt Feeder

Robust Belt Feeders that deliver a high-quality performance and long life by operating with efficiency and ease

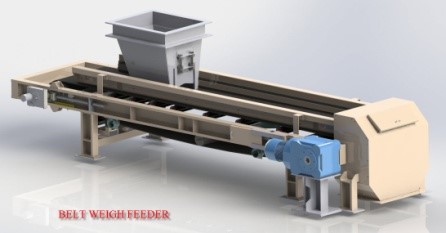

Belt Weigh Feeder

Autoweigh BWF is a belt weigh feeder with smart dosing control for continuous gravimetric dosing of all bulk materials. Provides High flexibility. High performance and Easy integration with supervisory automation systems

Belt Weigh Scale

Acme's AWBS series conveyor belt scales are custom-integrated to suit your conveyor. From logistics and warehousing to mining and industrial applications, Acme provides conveyor belt scales for a wide range of needs.

Silo/Bin Weighing

AHW series Silo/Bin weighing systems offer an accurate measurement of material stored. Specially designed load cell modules offer long term reliable performance. System offers wide ranging interface options with customer PLC/DCS

Loss In Weight Feeder

Autoweigh LIW is a Loss In weight feeder with smart dosing control for continuous gravimetric dosing of all powdered materials which provides High flexibility. High performance. Easy integration. Motorised agitators and Bin aeration systems ensure smooth material flow

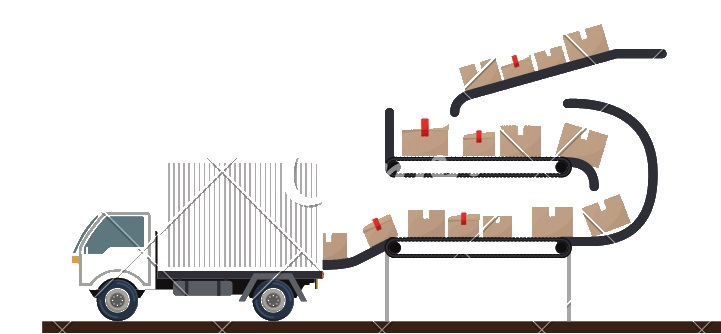

Online Bag Counting System

for loading points have proved to be an accurate tool for counting the bags loaded onto each wagon/truck. Centralised monitoring station with data logging monitors multiple such loaders from a remote location.

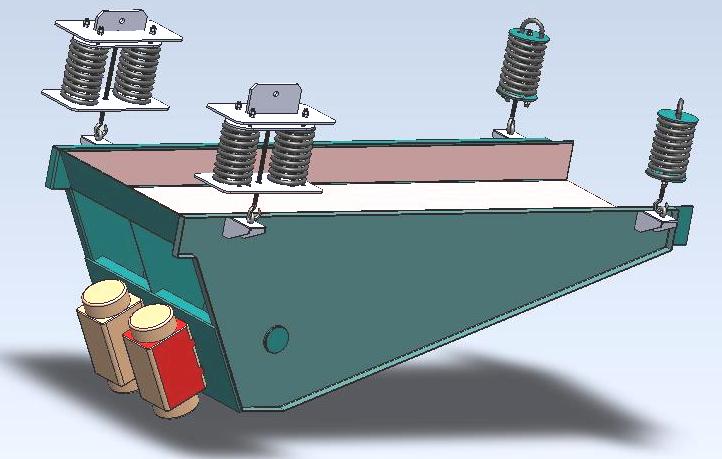

Vibro Feeders

AVF series Electro Mechanical Vibro feeder is an ideal extraction/conveying equipment for bulk materials. They can handle the largest quantities of materials and convey them to downstream process. Driven by robust unbalanced motors, they are specially adapted to the widest range of requirements.

Bulker Loading System

Acme’s AWB series vehicle scale with automated filling control is ideal for Bulk loading of cement/clinker in trucks/wagons. Accurate position control and traffic signals ensure fail safe operation of material loading with accuracy and efficiency

Truck Scales

AWB series Vehicle scales are ideal partner for all industries by accurately recording the incoming and outgoing materials. From logistics and warehousing to mining and Bulk loading areas, Acme provides Vehicle Scales for a wide range of needs.

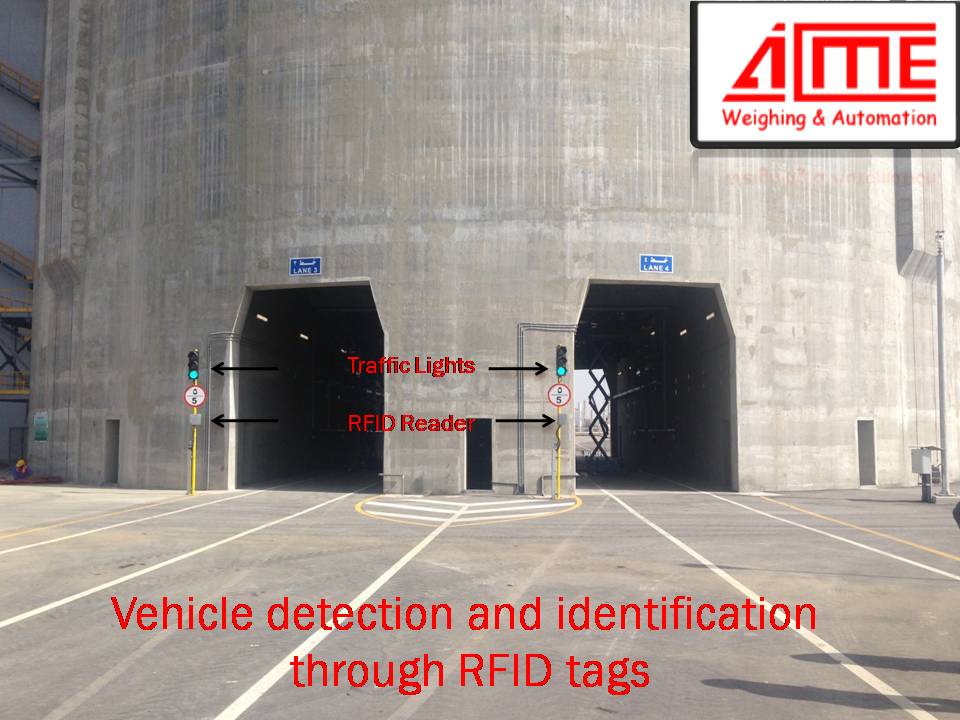

Unmanned Weigh Bridge

AWB series Mines Vehicle Scale systems offer an accurate measurement of raw material transferred from mines. Fully automated unmanned weigh bridges offer a trouble free dependable solution for huge volume of transactions

Static Rail Weigh Bridge

Acme’s AWB series Train scale is ideal for Bulk loading of finished goods in wagons while doing commercial transactions. Optional position control and traffic signals ensure fail safe operation of material loading with accuracy and efficiency